How To Diagnose a Walk-In Cooler That Isn’t Cooling Properly

A walk-in cooler is an essential part of many restaurants, school cafeterias and convenience stores’ daily operations. In other words, this appliance plays an essential role in your business activities. However, it’s often overlooked until problems start to pop up.

And, in some cases, emergency repairs might be needed, and it can be costly to cough up the cash for such repairs. That’s why, before your appliance needs to be repaired, it’s important to take the time to perform regular maintenance to catch those minor issues, before it’s too late!

Make Sure to Perform Regular Maintenance and Cleaning

The wise thing to do is to schedule preventive maintenance on all your foodservice equipment, before your walk-in cooler needs repair. How often you need to conduct regular maintenance checks will depend on a few factors, such as the type of walk-in cooler you have, as well as its make and model. Individual maintenance requirements will vary.

However, no matter what type of walk-in cooler you have, there are a few tips to keep in mind at all times. For instance, make sure that you’re not overfilling the cooler. Even though walk-in coolers are generally rather large, having too many products stored inside could impede proper air circulation, which might keep certain products at a different temperature than the rest.

Additionally, depending on where your walk-in cooler is located, it may require additional cleanings or maintenance. For instance, coolers in restaurant kitchens are prone to build-ups of grease and dirt, which will need to be cleaned more often than a cooler located in a convenience store setting. Any build-up of dust or extreme levels of humidity can impact the health of your cooler.

Also, never allow trash or other debris to gather around the cooler because that will hinder the appliance’s effectiveness. The area surrounding your condensing unit and evaporator must be clear at all times to ensure proper airflow to the unit’s condense coils.

Examine the Door for Air Leaks

Without an insulated door with a sight teal, your walk-in cooler will fail to keep cold air in and hot air out. With that said, the insulated door should be one of the very first things you check while performing maintenance.

If ice is accumulating or you’ve noticed excessive condensation around your door, then it is likely caused by a poor air seal. If your walk-in cooler’s door isn’t sealing properly, it means that cold air is escaping. The cold air that escapes and mixes with warm air condensation will form frost or condensation.

Alternatively, ice builds up around the bottom or sides of your door caused by a faulty defrost heater. With this in mind, make sure to regular check your cooler’s door to make sure that its seal or gasket is still intact. If it’s missing, broken, or simply worn-out from years or usage, it will need to be replaced.

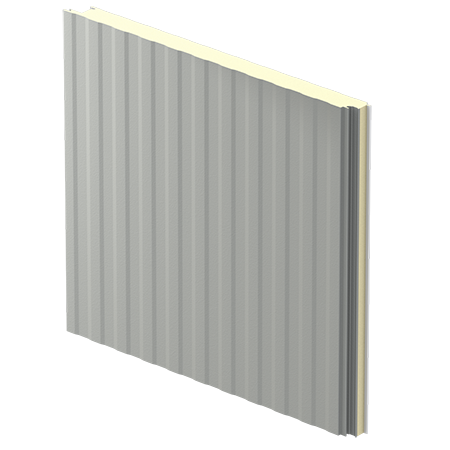

Examine Insulation Panels

Next, the unit’s insulation panels are just as crucial to the overall health of your walk-in cooler as the door is. This is because the panels, which include the walls, ceiling, and often the floor, help the unit retain colder temperatures. In turn, keeping your products at a steady, ambient temperature.

It is vitally important to maintain and clean the panels, doors and gaskets of your cooler. Keep all panel surfaces free of any liquid or solid spills. Clean up any messes in your walk-in cooler as soon as they happen.

Problems with the Compressor

The compressor works with other parts to add pressurize and circulate the unit’s refrigerant. The refrigerant or coolant circulated throughout your walk-in cooler works to cool down the air by absorbing heat and then dispersing it via the unit’s condenser coils.

When your unit’s compressor breaks down, or fails to circulate coolant, you’ll experience issues such as your unit not cooling down properly or being able to maintain a consistent temperature. While you may be able to diagnose many of your unit’s smaller issues, a faulty compressor usually requires the skills and knowledge of a trained appliance technician.